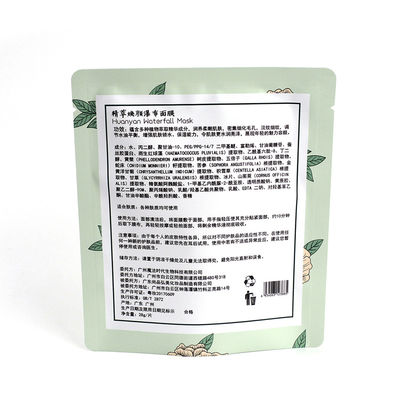

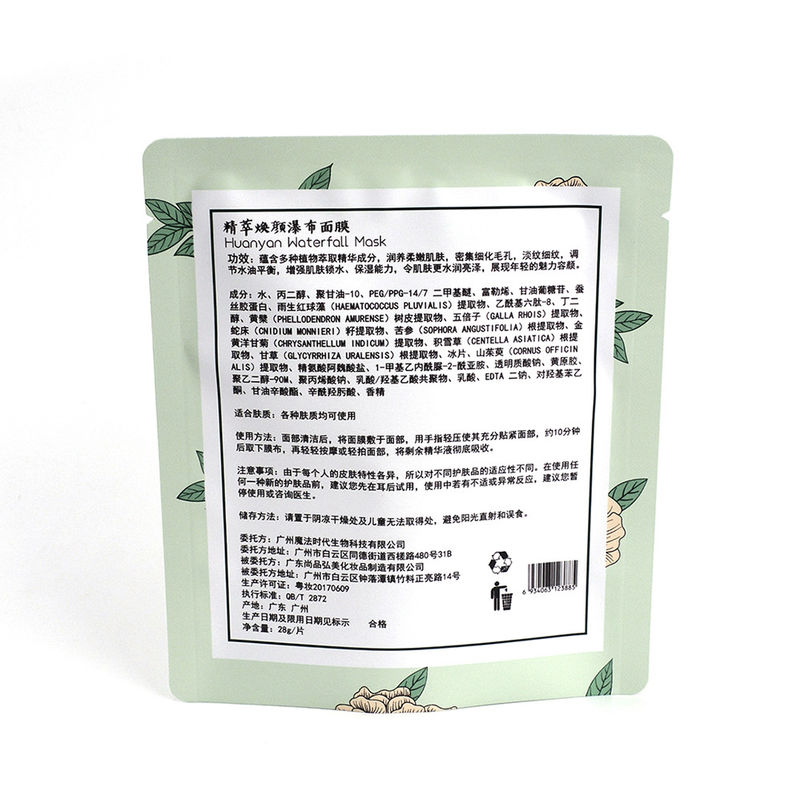

Semi VMPET PE 1KG Sealed Plastic Packaging With Zipper

Product Details:

| Place of Origin: | China |

| Brand Name: | JUNNAN |

| Certification: | CE/ROHS/FDA/SGS |

| Model Number: | 3SS03 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10000pcs |

|---|---|

| Price: | USD 0.02-0.05 and negotiation |

| Packaging Details: | Export standard packing. carton box+pallet. |

| Delivery Time: | 5-10days |

| Payment Terms: | L/C, T/T, Western Union,Paypal |

| Supply Ability: | 1000000pcs per month |

|

Detail Information |

|||

| Material: | PA/PE | Type: | Vacuum Pouch |

|---|---|---|---|

| Size Of Bag: | 23*48cm | Thickness: | 68um |

| Feature: | Waterproof,high Barrier,softness,durable,fashionable | Application: | Frozen Food Packaging |

| Certificate: | CE/ROHS/FDA/SGS | Product Name: | Material Bopp / Semi Vmpet / Pe Three Side Sealing Plastic Bag With Zipper |

| Highlight: | 1KG Sealed Plastic Packaging,PE Sealed Plastic Packaging,Semi VMPET vacuum package bags |

||

Product Description

Material bopp / semi vmpet / pe three side sealing plastic bag with zipper

Specifications:

| Name | Material bopp / semi vmpet / pe three side sealing plastic bag with zipper |

| Printing | Gravure printing |

| Printing Colors | Up to 9 colors |

| Process Type | Dry lamination |

| Quality requirement | High |

| Technique Level | High |

| Design Service | Optional |

| Net content | 1kg |

| Content | Snack food |

Our service:

1. Tell us the items details(material ,size,thickness and quantity).and then we will quote a nice price for you. (If the price is agreed by both parties, you have to pay a 50% down payment and 100% plate-making fee first.)

2. After we receive your down payment, we will start to produce the goods .

3. During the course of producing , we will send you the photos to check and confirm.

If everything is ok , you have to pay the balance amount before shipping.

Quantity assurance:

1. Established a procedure to check products at all stages of the manufacturing process - raw materials, in process materials, validated or tested materials, finished goods, etc. Besides, we have also developed a procedure which identifies the inspection and test status of all items at all stages of the manufacturing process.

2. 100% inspection in assembly lines. All controls, inspections, equipment, fixtures, total production resources and skills are inspected to ensure they consistently achieve the required quality levels .

![]()